Post by jlafrenz on Mar 24, 2012 18:34:05 GMT -5

Need some speaker stands on the cheap? Here you go. Just as with all the DIY projects I present you, these can be built with easy to find products and tools that just about everyone has in their garage. They can be built in an afternoon. These are a nice alternative to more expensive stands and they can be filled with weight and finished to your liking.

I will give some thoughts on finishing these at the end of the thread. I will discuss some of the materials there, as well. I will also discuss test fitting and the cutting of the thread rod depending on what height you need. I have put it at the end so that you can see the structure of the stand before worrying about test fitting.

Here is what you will need for tools and materials.

Tools:

Multiple Saws (Chop, table, circular, hack) - More on this to come

Tape Measure

Drill

Drill Bits

Forstner Bits

Socket Wrench

Wrench

Pencil

Straight Edge

Compass (optional, not the direction kind)

Materials:

PVC Pipe (3 inch)

Wood

Thread Rod

Jamb Nuts

Lock Washers

Flat Washers

Sand

Rope Caulk

Spikes/Feet

The first step is to cut your base and top pieces of the stands. Your choice of wood will vary depending on what look or finish you are going with. I used some 1x12 and 1x8 boards that I had left over in the garage. I usually make the base around 1'x1' and the top a bit smaller. This can vary again based upon the look you want and your speaker size.

You will also want to cut your PVC to the height of your choice. This is very simple to do yourself if you have a chop saw and a very fine tooth blade. Just clamp your PVC in place and go slow. You could cut it on a table saw or even by hand, but I don't feel those would be as easy. If you don't have access to these types of saws, hardware stores will usually cut the pipe for you or even have pre-cut pieces. Hand cut rarely comes out smooth unless you are really good.

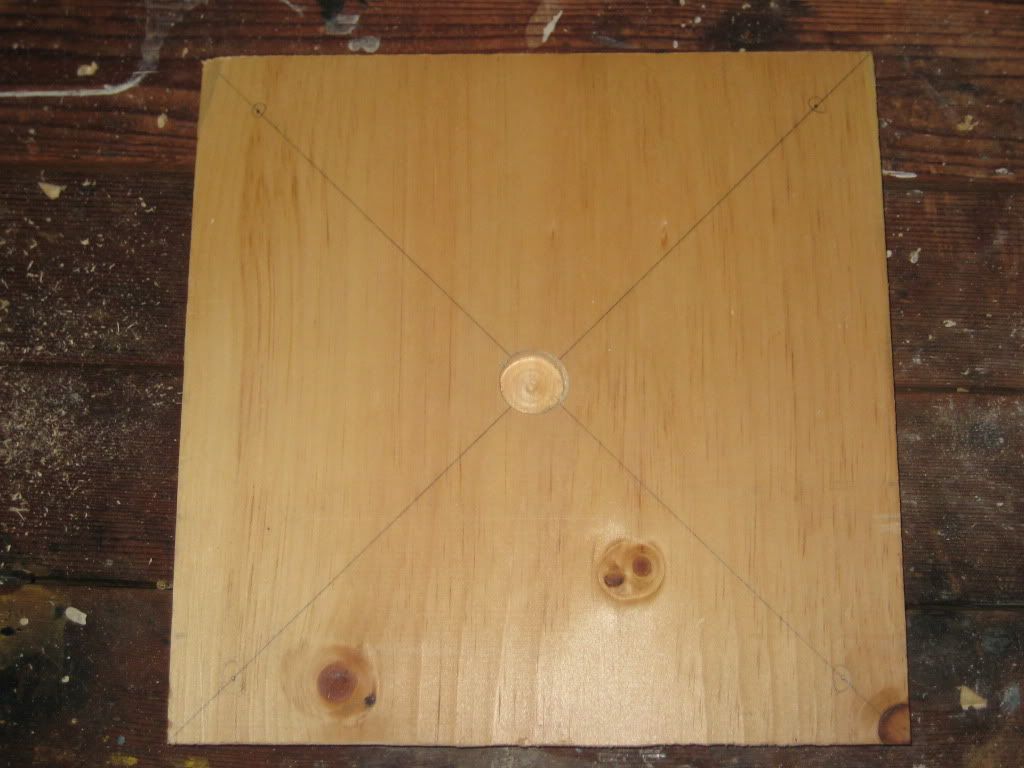

Once you have all your pieces cut, it is time to start making your marks to do some drilling. First find the center of your board by drawing a simple X from corner to corner. Then you can measure and mark where you want your spikes or feet to go if they require drilling. I measured in one inch from each side. The quick way to do this is measure where the diagonal is one inch away from one of the sides.

Then next step is optional and designed to help you keep your PVC centered on the top. On the reverse side of where you just made your marks, once again find the center. Then with the compass draw a 3 inch circle. This will help you line of the PVC in the center of your stand. If you finish your stands, you can do this after they are finished as the pencil marks will be hidden.

Now it is time to start drilling. The way I will show you how to drill and in what order is the same for the top and bottom pieces. You will only need to drill on one side of each of the pieces. The key to this is that you will be drilling the bottom of the board for the bottom section and the top of the board for the top section. Should be easy to remember. With your forstner bit, drill a hole directly in the center of the board, but DO NOT go all the way through. Go about half way or enough for a washer, lock washer and jamb nut to sit flush with the board. Make sure to use a bit that is wider than the flat washer and allows you to get a socket over the jamb nut.

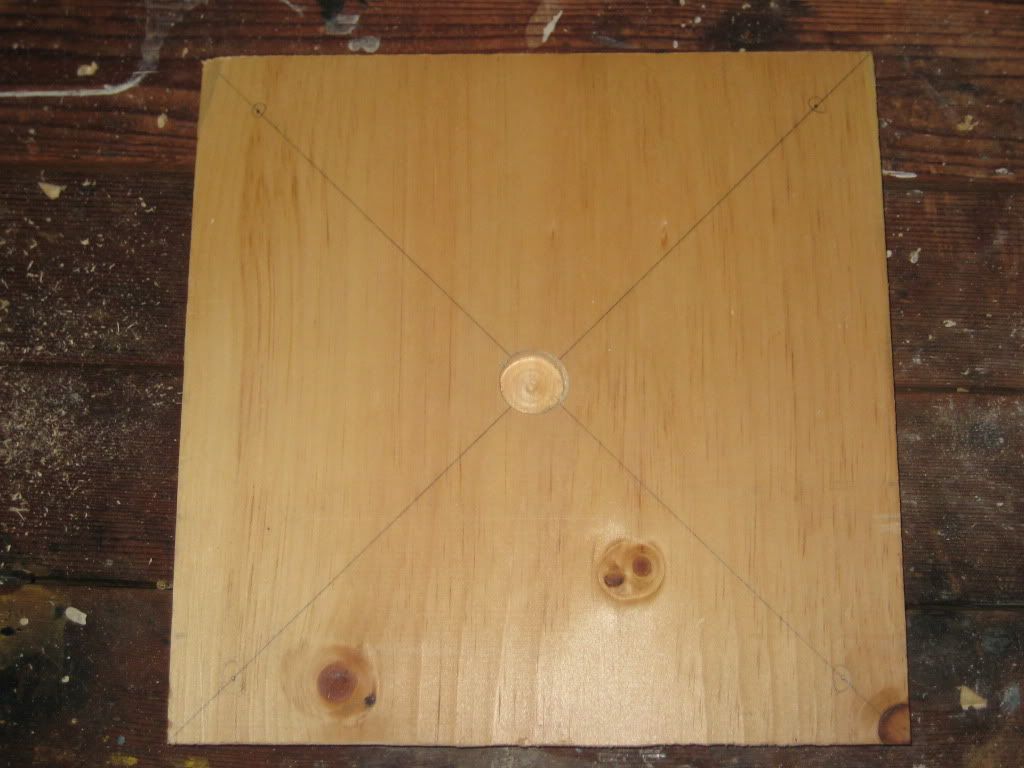

Now that you are half way (or so) through the board, change bits to a regular drill bit (or smaller forstner bit). Use the size bit of the thread rod you chose. I used 3/8 for this project, but you could go with thicker if your stand are going to be taller. The forstner bit should have left a point in the center of the hole for you. With your regular drill bit, again drill in the center, but this time you will go all the way through. It will look like this.

And this on top of the board.

Repeat this same process with the top pieces of your stands.

Now we are ready to connect the thread rod to the bottom board. Start by twisting a jamb nut on a little way onto the thread rod. Then put your lock washer and flat washer on in that order.

Insert the thread rod into the top of the board through the hole. We should have our larger hole on the bottom. In the following order: flat washer - lock washer - jamb nut, put these on the portion of the thread rod sticking out the bottom. Leave the jamb nut flush with the bottom of the thread rod and board.

With the socket on the bottom nut and a wrench on the top, tighten the nuts keeping the bottom one flush with the bottom of the board. This will keep your thread rod tight and hold it vertical. It is a little tricky since you don't have 3 hands, but you can easily tweak it so the thread rod is straight.

Grab your piece of PVC and on one end install the rope caulk. You can find rope caulk with the weather stripping if you are unfamiliar with what it is. The purpose if this is to make a seal and keep our sand (weight) from coming out the bottom. Try and keep it around the inner edge for the best finished look.

Now slide the PVC over the thread rod and press down firmly to adhere the rope caulk to the bottom of the board. That circle that we made earlier will help you line up your PVC and keep it centered.

It's starting to look like a speaker stand!! Pour your sand or whatever you have chosen to use for weight into the PVC trying to keep the thread rod centered. Pick the stand up by the thread rod and tamp lightly to help settle the sand. Pack it full. More weight is good.

It's time to install the top of the stand. With the larger hole facing up, slide it over the thread rod. It isn't necessary for you to put rope caulk on the top part, but you can if you like. Put your flat washer - lock washer - jamb nut on it that order. Tighten down the nut and your done. Make sure that it is flush so that it does not intrude with your speaker sitting flush or damaging the finish. **Refer to the test fitting section**

A finished product.

**TEST FITTING** Because thread rod comes if full foot increments, it may be necessary to cut it to size. After all you pieces are cut and the bottom portion is assembled, place the PVC over the thread rod and then the top plat on. If the thread rod is to long (there is a good chance it will be), mark where the thread rod is flush and will not interfere with the speaker on the stand or damage the finish. Cut the thread rod with a hack saw and then test fit again to make sure everything is flush before final assembly.

Here are a few tips on finishing. There are so many options and personal preference so I will keep it basic. The wood you choose only matters based upon how you want to finish the stands. If you want to stain them, you can use veneered plywood. Then finish the edges with some edge banding (iron on veneer for edges). If you plan to paint the wood, you can use either wood putty or Bondo to finish the cut edges. If you plan to paint the PVC, use very light sand paper or something that will scuff it slightly and help paint stick. I would also use primer. Products like textured paint or spray on bed liner have a finish that will help hide any swirls from the sand paper. If you want a high gloss finish, I am not the guy you want to get advice from. There are lots of very talented people here on this form who are more than willing to give you advice on finishing your stands for a look that will match your system so don't be afraid to ask for help.

I will give some thoughts on finishing these at the end of the thread. I will discuss some of the materials there, as well. I will also discuss test fitting and the cutting of the thread rod depending on what height you need. I have put it at the end so that you can see the structure of the stand before worrying about test fitting.

Here is what you will need for tools and materials.

Tools:

Multiple Saws (Chop, table, circular, hack) - More on this to come

Tape Measure

Drill

Drill Bits

Forstner Bits

Socket Wrench

Wrench

Pencil

Straight Edge

Compass (optional, not the direction kind)

Materials:

PVC Pipe (3 inch)

Wood

Thread Rod

Jamb Nuts

Lock Washers

Flat Washers

Sand

Rope Caulk

Spikes/Feet

The first step is to cut your base and top pieces of the stands. Your choice of wood will vary depending on what look or finish you are going with. I used some 1x12 and 1x8 boards that I had left over in the garage. I usually make the base around 1'x1' and the top a bit smaller. This can vary again based upon the look you want and your speaker size.

You will also want to cut your PVC to the height of your choice. This is very simple to do yourself if you have a chop saw and a very fine tooth blade. Just clamp your PVC in place and go slow. You could cut it on a table saw or even by hand, but I don't feel those would be as easy. If you don't have access to these types of saws, hardware stores will usually cut the pipe for you or even have pre-cut pieces. Hand cut rarely comes out smooth unless you are really good.

Once you have all your pieces cut, it is time to start making your marks to do some drilling. First find the center of your board by drawing a simple X from corner to corner. Then you can measure and mark where you want your spikes or feet to go if they require drilling. I measured in one inch from each side. The quick way to do this is measure where the diagonal is one inch away from one of the sides.

Then next step is optional and designed to help you keep your PVC centered on the top. On the reverse side of where you just made your marks, once again find the center. Then with the compass draw a 3 inch circle. This will help you line of the PVC in the center of your stand. If you finish your stands, you can do this after they are finished as the pencil marks will be hidden.

Now it is time to start drilling. The way I will show you how to drill and in what order is the same for the top and bottom pieces. You will only need to drill on one side of each of the pieces. The key to this is that you will be drilling the bottom of the board for the bottom section and the top of the board for the top section. Should be easy to remember. With your forstner bit, drill a hole directly in the center of the board, but DO NOT go all the way through. Go about half way or enough for a washer, lock washer and jamb nut to sit flush with the board. Make sure to use a bit that is wider than the flat washer and allows you to get a socket over the jamb nut.

Now that you are half way (or so) through the board, change bits to a regular drill bit (or smaller forstner bit). Use the size bit of the thread rod you chose. I used 3/8 for this project, but you could go with thicker if your stand are going to be taller. The forstner bit should have left a point in the center of the hole for you. With your regular drill bit, again drill in the center, but this time you will go all the way through. It will look like this.

And this on top of the board.

Repeat this same process with the top pieces of your stands.

Now we are ready to connect the thread rod to the bottom board. Start by twisting a jamb nut on a little way onto the thread rod. Then put your lock washer and flat washer on in that order.

Insert the thread rod into the top of the board through the hole. We should have our larger hole on the bottom. In the following order: flat washer - lock washer - jamb nut, put these on the portion of the thread rod sticking out the bottom. Leave the jamb nut flush with the bottom of the thread rod and board.

With the socket on the bottom nut and a wrench on the top, tighten the nuts keeping the bottom one flush with the bottom of the board. This will keep your thread rod tight and hold it vertical. It is a little tricky since you don't have 3 hands, but you can easily tweak it so the thread rod is straight.

Grab your piece of PVC and on one end install the rope caulk. You can find rope caulk with the weather stripping if you are unfamiliar with what it is. The purpose if this is to make a seal and keep our sand (weight) from coming out the bottom. Try and keep it around the inner edge for the best finished look.

Now slide the PVC over the thread rod and press down firmly to adhere the rope caulk to the bottom of the board. That circle that we made earlier will help you line up your PVC and keep it centered.

It's starting to look like a speaker stand!! Pour your sand or whatever you have chosen to use for weight into the PVC trying to keep the thread rod centered. Pick the stand up by the thread rod and tamp lightly to help settle the sand. Pack it full. More weight is good.

It's time to install the top of the stand. With the larger hole facing up, slide it over the thread rod. It isn't necessary for you to put rope caulk on the top part, but you can if you like. Put your flat washer - lock washer - jamb nut on it that order. Tighten down the nut and your done. Make sure that it is flush so that it does not intrude with your speaker sitting flush or damaging the finish. **Refer to the test fitting section**

A finished product.

**TEST FITTING** Because thread rod comes if full foot increments, it may be necessary to cut it to size. After all you pieces are cut and the bottom portion is assembled, place the PVC over the thread rod and then the top plat on. If the thread rod is to long (there is a good chance it will be), mark where the thread rod is flush and will not interfere with the speaker on the stand or damage the finish. Cut the thread rod with a hack saw and then test fit again to make sure everything is flush before final assembly.

Here are a few tips on finishing. There are so many options and personal preference so I will keep it basic. The wood you choose only matters based upon how you want to finish the stands. If you want to stain them, you can use veneered plywood. Then finish the edges with some edge banding (iron on veneer for edges). If you plan to paint the wood, you can use either wood putty or Bondo to finish the cut edges. If you plan to paint the PVC, use very light sand paper or something that will scuff it slightly and help paint stick. I would also use primer. Products like textured paint or spray on bed liner have a finish that will help hide any swirls from the sand paper. If you want a high gloss finish, I am not the guy you want to get advice from. There are lots of very talented people here on this form who are more than willing to give you advice on finishing your stands for a look that will match your system so don't be afraid to ask for help.

We spilled some sand onto my silicone caulk to seal the bottoms as well. I've planned much better for my next iteration.

We spilled some sand onto my silicone caulk to seal the bottoms as well. I've planned much better for my next iteration.