harri009

Emo VIPs    ReferenceAnalog.com

ReferenceAnalog.com

Posts: 1,425

|

Post by harri009 on Sept 4, 2013 15:47:59 GMT -5

Looking good buddy!!

|

|

|

|

Post by gregd on Sept 4, 2013 16:51:12 GMT -5

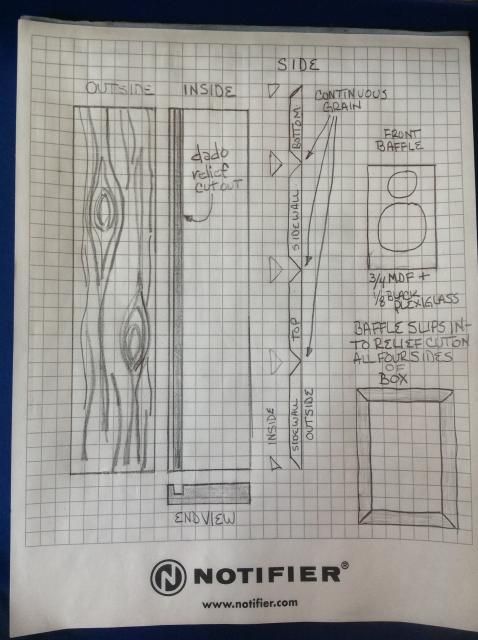

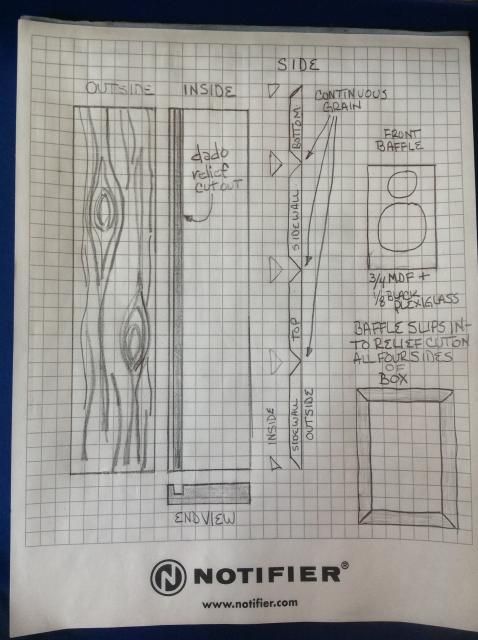

First drawing:  Does this make any sense? Ahh, I see it now. No cross-grain joints since the front and back are mdf or ply, and those join to long grain. That should work. The continuous grain is a cool idea although it will run "up" one side and "down" the other. Depending on the grain this may look just fine. I don't see any particular advantage in carrying the grain around the bottom unless you are planning for stands that won't cover it. I don't think you want to do the baffle in a dado. Then you have protrusions in front of the baffle which I presume is undesirable. One trick you could consider for the front/back is this: Once you surface, plane, and joint the board, rip strips off both edges of the board that are a bit more wide than the baffle & back are thick. Use these strips to edge band the baffle and back with mitered corners, and then glue these assemblies on. If you orient things correctly the grain will match back up. Just make sure that edge banding is flush with the outside face of the baffle/back, and that the edge-banded baffle/back dimensions are either dead-on or slightly oversized. After gluing them on use a flush trim router bit to make them perfectly flush with the sides. Yes, this means you will have 2 glue joints running around the sides/top of the cabinet, but since the grain is mostly parallel to the joint it will be very hard to see so long as you get it tight. |

|

|

|

Post by Darksky on Sept 4, 2013 17:40:55 GMT -5

I had not thought about the grain running up one side and down the other. I will really look at the stock to see if there are any spots that will look oddor directional.

As far as the lip on the front, I thought I would set it to be about 3/32nds proud and angle it back at 15 degrees or so. I know that is probably not as acoustically as good as a radius, but the tiny lip would work as a frame or keeper for a grille. I think theyneedgrilles. One nice thing about using the MDF+plexi is that it makes setting magnets in the face simple.

The idea of covering the butt joints with strips on the faces would work well, but it is exacting work. Why wouldn't you drop the back in as I had described. I was thinking that the rim joist pieces would help to stiffen the box, I have room to pare on the overall depth of the cabinet there as well. The original drawings call for 10.5 inches with front and back dropped on. I have a strong 12 inches there.

What would you think of matching wood on the rear instead of MDF+ plexi?

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 4, 2013 18:07:24 GMT -5

Bradley, I will follow your new speaker project with great interest as I did with your gorgeous sub. The best part of this is that your son, Lucas, is going to be able to help build his own great speaker with his dad. He will learn so much and have the wonderful time spent together on this project. IMO this will be slightly superior to the boombox that was suggested for his birthday present.  Great Dad! |

|

|

|

Post by Darksky on Sept 4, 2013 23:49:36 GMT -5

Thanks Chuck, I think this will be a good project for us both. He is excited to begin making sawdust. |

|

|

|

Post by gearhead2003 on Sept 5, 2013 1:16:11 GMT -5

^^^Awsome pic Dark

|

|

|

|

Post by gregd on Sept 5, 2013 15:56:52 GMT -5

One trick you could consider for the front/back is this: ... Yes, as you point out, that is going to be a bit of a PITA. As I understand it the baffle will be built up from MDF glued to black plexi. An easy thing to do would have the black plexi overlay the front edge of the speaker. The MDF could be cut slightly undersized to fit between the sides and the top/bottom - a small gap won't matter since it will be hidden by the plexi. Use epoxy or some other gap-filling glue to attach the baffle to the cabinet. From the side you would only see the edge of the plexi which would still look good if you buff it up nice. The back could go on as you describe. Undersize the back a smidgen and when you glue it in place take the time to center it and the gap will look like a design feature. |

|

|

|

Post by Darksky on Sept 6, 2013 20:01:10 GMT -5

One trick you could consider for the front/back is this: ... Yes, as you point out, that is going to be a bit of a PITA. As I understand it the baffle will be built up from MDF glued to black plexi. An easy thing to do would have the black plexi overlay the front edge of the speaker. The MDF could be cut slightly undersized to fit between the sides and the top/bottom - a small gap won't matter since it will be hidden by the plexi. Use epoxy or some other gap-filling glue to attach the baffle to the cabinet. From the side you would only see the edge of the plexi which would still look good if you buff it up nice. The back could go on as you describe. Undersize the back a smidgen and when you glue it in place take the time to center it and the gap will look like a design feature. I like the idea of insetting the piece for the rear. I think the inner lip or rim joist will add strength to the box and help to minimize any flex and reduce vibration. I will make all the bracing out of heavy oak pieces. I hate to lose the look of a one inch thick piece of wood all the way around the plexi on the front baffle. I suppose instead of dado cutting into the wood and slipping the MDF front baffle into place, I could do the same thing as the rear and set a lip (rim joist) 7/8 back from the front of the box. That would allow the front baffle to sit inside the box- but it would rest with the plexiglass at the finished depth as the front edge of the box. I would still angle the box edges back at about 15-20 degrees. I think that would have about the same effect as a round over or radius. When I put a grille cover on though, I think it will look funny because it will stick out further than the edges of the box. One thing to remember, when the drivers are installed, they sit proud of the front of the baffle. The spider of the woofer folds into the rim and makes the driver sit on top of the face of the baffle. It is almost 1/4 of an inch thick. |

|

|

|

Post by Darksky on Sept 6, 2013 20:13:18 GMT -5

Look at this baffle  Notice how the cutout for the woofer is designed for the driver to sit completely on top. The tweeter is set into the frame slightly. I will accomplish this with the 1/8 thickness of the plexiglass. I t has to be notched out slightly at the bottom to accommodate the wiring hookup.. Look at the thickness of the grille frame in the picture. Mine will be slightly thinner and I will radius all the inside edges to reduce its impact on imaging. What would it hurt if my grille frame was one inch smaller all the way around and inset into the box slightly? The wooden lip all the way around would be equal or slightly less than the thickness of the grille, and it would angle back to mimic a radius. Do you guys think this will have a big impact on anything? |

|

DYohn

Emo VIPs

Posts: 18,485

|

Post by DYohn on Sept 8, 2013 22:45:36 GMT -5

Milling your own lumber is wonderful and I am absolutely jealous of your ability to do that. I've built loudspeakers from 1/1 cherry and was worried about resonance so I planed to back the hardwood with MDF but instead I ended up doing exactly what you seem to be planning: MDF for front and rear baffle and hardwood for the 4 sides with no MDF. I added an MDF brace glued in just above the woofer connecting all four sides and perforated with 2" holes. The enclosure worked perfectly. In fact you may find you do not need the no-rez at all, but if you have it already you will do no harm using it.  I also stuffed with 1/2 pound of polyfill. As to driver mounting, surface mount the woofer and flush mount the tweeter is a common method for a 2-way system. Go for it. |

|

|

|

Post by ocezam on Sept 9, 2013 7:35:41 GMT -5

I'm from Southern CO also. Beetle kill pine is beautiful when when finished. I hope the pieces you select show the blue veins. Great project, great thread.

|

|

|

|

Post by gregd on Sept 9, 2013 10:43:30 GMT -5

The baffle on my Klipsch Heresey 2 speakers is inset from the front edge of the cabinet sides like your plan. I don't know whether it is substance or fantasy, but some people seem to think the speaker performs best if the front baffle is the way it is supposed to be (height, width, edge radius, etc.). For example, Emotiva thinks the sculpting of the Stealth baffles adds to sound quality.

By all means, do it so you get the look that _you_ want.

For me it would take quite some time to get the 12" long beveled corners cut and fit to my satisfaction in stock that thick. Good luck!

|

|

|

|

Post by Darksky on Sept 9, 2013 16:03:31 GMT -5

I'm from Southern CO also. Beetle kill pine is beautiful when when finished. I hope the pieces you select show the blue veins. Great project, great thread. Wait until you see how pretty this lumber is turning out. Blue, gold and red. I have to wait until Friday to get time on a planer that is big enough to work the foot wide stock. I have decided that I am going to use the hardwood for the rear baffle as well. I am going to inset it as well, like we discussed earlier in the thread. I think it will look best that way. As far as the lip on the front baffle, I am going to make it slightly proud and angle cut it back. It will not be rounded over like a radius. It will be a straight cut, angled back at about 20 degrees. I have an idea about building a pair of additional (sub) woofers to accompany the bookshelves. I hesitate to. Refer to them as subs, because they will only be eight inch. More on that later - Thanks for chiming in David. I always appreciate your ( and everyone else's) perspective. These boxes are going to be BEAUTIFUL. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Sept 10, 2013 23:33:24 GMT -5

" I hesitate to. Refer to them as subs, because they will only be eight inch. " Don't hesitate. I have owned and heard a number of excellent 8" sub's. My Mirage Omni S8 is a great musical addition to my Airmotiv 4's. I owned the original Energy Take Five system which had the Energy S8 sub. It was rated by HT Magazine and a number of other reviewers as one of the best 8" subs they have ever tested. My son, who was a drummer at the time heard my Energy 8" sub (I had EQ's it with the low end of an ART EQ and it was very flat down to about -28Hz). He thought it was an awesome sub playing his Planet Drum CD. The plan it to place it in the best location and EQ if necessary. If I were buying a sub today for a music system in a smaller room at reasonable levels I would definitely look at an 8" model. Many of the best are flat, transient and musical. Blending with the mains is critical. Most folks have the sub gain too high and can hear the sub as a separate source. An 8" driver is all you need for excellent response for music down the 30Hz area in a smaller room at less than maximum loudness. |

|

|

|

Post by gregd on Sept 12, 2013 9:10:13 GMT -5

First drawing:  Does this make any sense? Some more thoughts on the cabinet. From what I have seen, most speakers with wood-grain finishes are veneer over MDF or other dimensionally stable material. You could do that here - just resaw your wood into veneer. If you want to use solid wood, you really do need to accommodate wood movement in any cross-grain joint unless these are really small boxes. Frame-and-panel construction accommodates wood movement in cross-grain joints by trapping the panel in a groove so that it slide around a bit. Even then, if the fit of the panel in the groove is too tight the panel can split. This might not work so well for speakers that need to be air tight. Yours are ported, and someone knowledgeable of speaker design might be able to say how "air tight" the box needs to be. If the box must be air tight, one option is to use two panels: an inner panel of MDF or plywood that will be glued and a decorative panel of solid wood that will float. I would cut a 1/8" rabbit on the side of the MDF facing the decorative panel to keep glue squeeze-out away from that. I also might wax the edges of the decorative panel just in case some glue manages to get to it anyway. Another consideration with panel construction is whether the surface of the panel is recessed or flush with the frame - in this case the edges of the sides. It just occurred to me that raised panels are usually flush with the frame; they just have a wide, decorative rabbit. So for flush panels, simply rabbit the edges so that the depth of the rabbit matches the distance to the edge of the groove to the edge of the side. But in order to accommodate wood movement you need to allow for maybe a 1/32" gap to show. If the panel is pinned at its center to the inside MDF panel so that there is even spacing all the way around the panel you will have a nice looking detail. If the panel is the back of the speaker it probably doesn't matter much whether it is flush or recessed, but in any event mounting the binding posts along the centerline will do a nice job of pinning the panel - just line up the panel before you machine the opening and drive the screws. I'm not exactly sure how one could get this to work for the baffle. You wouldn't want the mounting screws of a large woofer going through the decorative panel. Maybe the baffle needs to be MDF or plywood veneered with material cut from your solid stock. If your speaker is going to be a box with flat sides and square corners I see no advantage and a lot of trouble building it from solid stock rather than veneer over MDF. Big advantages of using solid stock would be that it allows you to round over or otherwise form the corners, or even sculpt or shape the sides. Good luck! |

|

|

|

Post by Darksky on Sept 16, 2013 12:36:47 GMT -5

Sorry for the lack of progress lately. I have been sidetracked by another project, plus we have gotten some weather. It usually rains very littler this part of Colorado. This last week it has rained more than in the last few years combined. There has been a foot of rain this last weekend. An amazing amount of water. The county road a quarter mile from my driveway:  This is after the water receded. The bottom of my driveway:  The "dry" arroyo across the road from my place:  In addition, we had a tragic hunting accident:  He is on the path to a full recovery. |

|

USAFRetired

Sensei

New Receiver onboard Denon RIP

New Receiver onboard Denon RIP

Posts: 651

|

Post by USAFRetired on Sept 16, 2013 12:50:13 GMT -5

Pretty funny. Thanks for the laugh. Not the water damage though. That's scary. .

|

|

|

|

Post by Darksky on Sept 17, 2013 0:04:38 GMT -5

Okay, back on track.

I was considering building a set of passive 8 inch sub woofers to go with the bookshelves. Danny Richie has inexpensive 8 inch drivers that match the woofers in the LS Encores. They would only require one cubic foot of space in a sealed enclosure. I could easily build two additional small boxes to go with the bookshelf speakers. I thought they would look great. I could build two, one for each side. It would work perfectly. I have bought a used Rotel 1066 amplifier on the cheap from a member here. It is a six channel amp that is bridgeable. I thought "great" we can experiment a little- run the front l/r and bridge the other four to drive a L and R sub or bridge the fronts and drive the subs on one channel each. Or just dedicate one channel to each of the four speakers and leave the extra two channels dormant. Heck , if the bookshelves were set up differently I could bi amp them and then run the subs on one channel each. Too much fun right?

Apparently not:

I asked Danny about running the subs passively. He said NO- period.

He said that the crossover that would allow the subs to function correctly would result in enough delay that you would encounter so much difficulty with getting them in phase that it would not be worth the effort. He suggested that if I wanted to go with subs, I should only consider making them active. Using a plate amp that would be able to cross them over correctly and adjust for phase. That makes sense to me, but I am sad that I can't easily build two sub boxes and hook them up to left and right channels and have stereo woofers to accompany fhe bookshelves.

They would look so cool. Two small matching boxes with a single eight inch driver. I could run them off my existing amp and be able to futz around with different configurations and placements within the room. It would be a great tool to use to teach my Son and fun too.

What do you think?

Remember, this is a low budget set up to be used as a starter system for my boy, so nothing crazy complicated or too expensive.

For example:

I just was able to find (eBay) a Rotel 1050 DVD player. It will be used as his CD player. It matches aesthetically with the amp perfectly. It has all the control buttons laid out simply on the front panel, has a great simple remote with a volume control. It is supposedly a very good CD player. I purchased it for him - delivered for a whopping $42 USD.

How perfect is that for a system that he will literally be building himself? He is begging to begin practicing to solder, so that he will be able to wire the crossovers to the drivers and connection cups.

I just thought the passive subs would have been great.

|

|

|

|

Post by PGT on Sept 17, 2013 7:08:46 GMT -5

why not use something like a Crown XLS-1000? Onboard crossover, small and efficient. It doesn't have phase control but you can handle +/- by swapping the leads (180 degrees).

|

|

|

|

Post by Darksky on Sept 17, 2013 9:17:46 GMT -5

I am not familiar with any of the PRO audio products, so I don't know.

|

|