|

|

Post by Priapulus on Dec 31, 2013 12:53:56 GMT -5

I notice that some speakers, turntables, etc stand on conical spikes; supposedly to reduce the transmission of vibrations? There is also a huge aftermarket sale of these spikes. I understand how mass and flexible rubber links could dampen vibrations, but don't see how points do the same. I want to cry "snake oil", except my respected Paradigm speakers are supplied with points.

So is it snake oil? How does it (allegedly or actually) work (or not work)?

I ask because I'm trying to decide if my turntable rebuild should have new rubber feet, or some sexy brass pointy ones! |

|

|

|

Post by RightinLA on Dec 31, 2013 12:58:31 GMT -5

The significant reduction of contact surface area achieved by the use of spike supports or feet significantly reduces the amount vibrational transfer between the components that are in contact with each other. Depending on the type of rubber used, it may or may not reduce the transfer as much, but it is generally much kinder to the surface it comes in contact with. When using spikes, one must consider using suitable spike receptacles to avoid surface damage.  |

|

|

|

Post by Boomzilla on Dec 31, 2013 13:11:12 GMT -5

The purpose in spikes, for speakers, is a bit different. Some (narrow) speakers are unstable on carpeted floors. By fitting the speakers with "carpet piercing spikes," the speakers have firm support and are less likely to tip. The secondary purpose of speaker spikes is the vibrational transfer that RightinLA mentions - the concrete subfloor typically doesn't vibrate (except during earthquakes).

|

|

|

|

Post by jlafrenz on Dec 31, 2013 13:15:47 GMT -5

|

|

|

|

Post by RightinLA on Dec 31, 2013 13:32:25 GMT -5

Priapulus was principally concerned about the use of spikes with respect to his turntable rebuild. This is where vibration is the biggest concern.

"I ask because I'm trying to decide if my turntable rebuild should have new rubber feet, or some sexy brass pointy ones!"

|

|

stiehl11

Emo VIPs    Give me available light!

Give me available light!

Posts: 7,269

|

Post by stiehl11 on Dec 31, 2013 14:28:52 GMT -5

I use rubber isolation plugs that we use in front-end modules (where your radiator sits in your car) that are engineered specifically to dampen low-frequency and ultra-low-frequency vibrations (so the aluminum foil that is folded and brazed into a functioning radiator doesn't shake apart) for my speakers that sit on my dresser in my bedroom. They have completely eliminated any additional and unwanted "boom" that I was getting from, effectively, the big wooden box they were sitting on. And, even when I have the volume way-up are not transferring any noticeable vibrations to my equipment that is also sitting on the same dresser between the two speakers. While I won't dispute the statistics and measurements prestidigitated by audiophiles; if metal worked as a dampening agent, we'd use more of it.  |

|

|

|

Post by Priapulus on Jan 2, 2014 14:42:01 GMT -5

Thanks for all the suggestions. From experience I know that even a tiny point (ironically, like a phonograph needle!) transmits vibrations well; so despite the cones being so sexy, I'm going with soft rubber. I may set the turntable on a 2" marble plinth (for mass) which itself is floating on rubber, as a vibration shield. We used to use something like that for microscopes.

|

|

|

|

Post by Gary Cook on Jan 2, 2014 14:54:07 GMT -5

My rule of thumb, spikes go on speakers (to lock them to the floor) and insulators go on on turntables (to isolate them).

Happy New Year

Gary

|

|

KeithL

Administrator

Posts: 10,261

|

Post by KeithL on Jan 2, 2014 14:59:11 GMT -5

I read the claim somewhere (I forget where) that the point contact was supposed to work well to transmit vibration from the point to the floor, but less well in the reverse direction - with the result that the vibration "was drained from the turntable" but wasn't "transmitted back into it". (In other words, the spikes allowed excess energy to exit while not allowing vibration to enter.) I don't recall any proof to back this claim up, however. I think I much prefer the idea of a heavy mass plinth on a vibration absorbing rubber isolator. Sorbothane, which is specially formulated to absorb vibrations exceptionally well, can be purchased from a number of sources these days - and is a good choice there. (The technology behind Sorbothane is "real", and it really does absorb vibration much better than other types of rubber. ) There ARE two things you should know about Sorbothane: 1) The squishiness (viscosity) and size of Sorbothane feet are matched to the mass of what you plan to support. Therefore, you should always buy Sorbothane feet or pads such that the total load you put on them is between about 50% and about 75% of their "rated load". If you go much over or under that, they don't work nearly as well. (If your plinth and turntable together weigh 25 pounds, then four 10 pound rated feet would be a good choice.) 2) Sorbothane feet are usually sold with peel-off adhesive on one side; and Sorbothane has lots of plasticizer in it (it's sort of permanently "tacky" to the touch)... Both of these will often mar wood or other delicate surfaces. Therefore it might make sense to put small metal or plastic discs (or even waxed paper) between the Sorbothane and any surface you are especially worried about. Thanks for all the suggestions. From experience I know that even a tiny point (ironically, like a phonograph needle!) transmits vibrations well; so despite the cones being so sexy, I'm going with soft rubber. I may set the turntable on a 2" marble plinth (for mass) which itself is floating on rubber, as a vibration shield. We used to use something like that for microscopes. |

|

|

|

Post by lionear on Jan 8, 2014 0:21:52 GMT -5

Here's an interesting article on spikes: www.kosmic.us/Genesis%20Loudspeaker%20Coupling%20&%20Decoupling.pdfMy experience with Sorbothane is that is sucks the life out of the music! May be I didn't have the right amount in the right spot. There are a lot of ideas on vibration control for turntables. There are special vibration control platforms used in high-precision measurements - engineered for performance down to 1 Hz or even lower. People have also reported great results by putting 3 tennis balls under the turntable platform (with some way to keep the balls from rolling away, of course), sandwiching a bicycle inner tube between two boards. Are there any other ideas? |

|

kml

Sensei

King o' lamp cord

King o' lamp cord

Posts: 235

|

Post by kml on Jan 8, 2014 16:49:30 GMT -5

[quote author=" stiehl11" source="/post/599905/thread" timestamp="1388518132"While I won't dispute the statistics and measurements prestidigitated by audiophiles [/quote] LOL!!!! Too funny! You left out extended sighted listening test though... Thanks for the laugh.  cheers ken |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jan 8, 2014 16:54:15 GMT -5

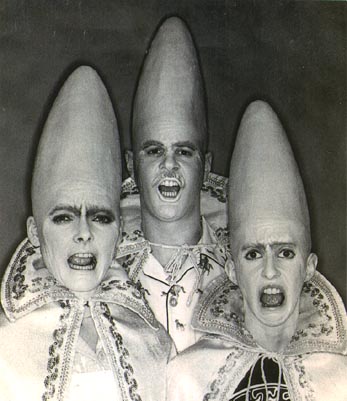

Maybe these folks might have some ideas.  |

|

|

|

Post by lionear on Jan 11, 2014 16:17:12 GMT -5

I love this video: www.youtube.com/watch?v=i9oZKfkQaQoI forgot about the "put the turntable on a big trough filled with sand" trick. Now that we have CNC machines, it should be possible to make platters and even bearings a lot more easily than in the 70's…. |

|